Production

Production

Production

Manufacturing Process

At our company, we follow a comprehensive manufacturing process to ensure the production of high-quality products. Each step is carefully executed by our skilled team to deliver exceptional results. Here is an overview of our manufacturing process:

Research and Development (R&D)

Our journey begins with thorough research and development. Our team of experienced professionals works diligently to design innovative and functional products that meet the evolving needs of our customers.

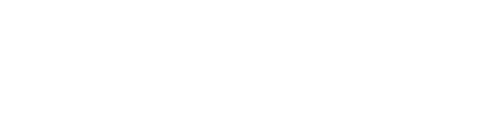

Mold Making

Once the design is finalized, we proceed with mold making. Our skilled technicians utilize advanced techniques and machinery to create precise and durable molds, ensuring consistent and accurate production.

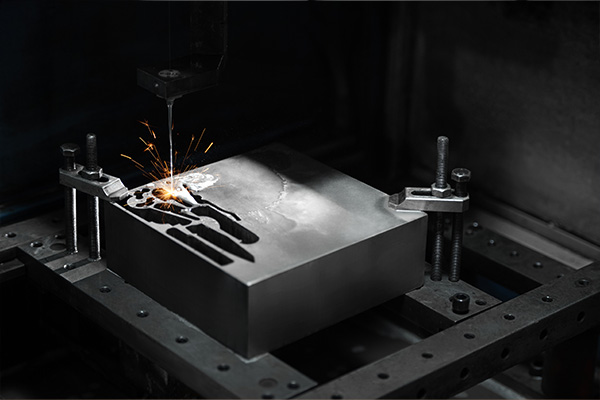

Stamping

The next step involves stamping, where the raw materials are transformed into desired shapes using specialized equipment. This process ensures the formation of precise components with excellent structural integrity.

CNC Machining

We utilize state-of-the-art CNC machines to perform precision machining. This computer-controlled process guarantees exceptional accuracy and allows us to achieve intricate details and fine finishes on our products.

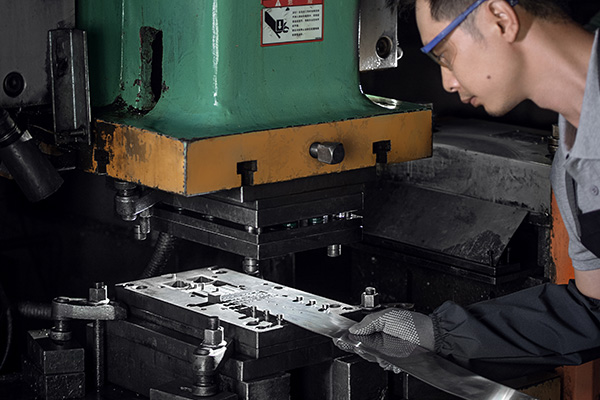

Laser Cutting

Laser cutting technology is employed to precisely cut and shape the materials according to the design specifications. This process enables us to create intricate patterns and intricate details with remarkable precision.

Sanding

After Stamping, our skilled craftsmen perform sanding to smoothen rough edges and surfaces. This meticulous process ensures a flawless finish and enhances the overall aesthetics of our products.

Heat Treatment

Certain products undergo heat treatment to enhance their strength, durability, and performance. This controlled heating and cooling process improves the material properties, making them more resilient and long-lasting.

Water Cooled Grinding Edge

We employ water-cooled grinding techniques to refine and sharpen the cutting edges of our products. This process ensures optimal sharpness, precision, and longevity, making our tools and knives highly effective for various applications.

Vibration Polishing

To achieve a premium and polished appearance, our products undergo vibration polishing. This technique smooths the surfaces, removes imperfections, and enhances the overall visual appeal of our offerings.

Assembly

Skilled technicians meticulously assemble the various components to create the final product. Each piece is carefully fitted and secured to guarantee functionality and reliability.

Full Inspection

Quality is our utmost priority. Every product undergoes a comprehensive inspection to ensure it meets our stringent standards. Our dedicated quality control team conducts rigorous tests and checks for any defects or deviations, ensuring that only top-quality products reach our customers.

Cleaning & Packaging

Before packaging, our products undergo a thorough cleaning process to remove any dust or debris, ensuring they are delivered in pristine condition. We then carefully package each item, considering its nature and requirements, to ensure safe transportation and presentation to our customers.